Insulation is essential for maximising energy efficiency at a time of growing environmental consciousness and rising energy bills. Thermal insulation, sometimes known as calorifugeage, is the process of shielding surfaces, ducts, and pipelines from heat gain or loss. The best methods for both exterior and interior insulation are covered in this extensive 2025 reference, along with their advantages and a thorough cost analysis to assist you in making wise choices.

Calorifugeage: What is it?

Insulating pipes, HVAC systems, tanks, and building surfaces to lessen heat transfer is known as calorifugeage. It is frequently used to increase energy efficiency, stop condensation, and shield equipment from temperature changes in commercial, industrial, and residential environments.

There are mostly two kinds:

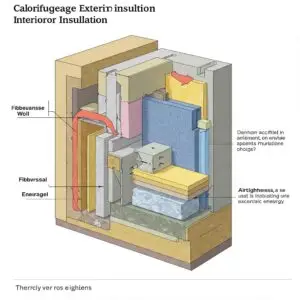

- Inside buildings, interior insulation (ITI) is used to insulate pipes, walls, floors, and ceilings.

- Installed on external walls and surfaces, exterior insulation (ITE) creates a thermal envelope.

Methods for Insulating the Interior (ITI)

1. Providing Internal Wall Insulation

- Method: Sandwiching metal or timber frames with insulating materials such as mineral wool, polyurethane foam, or polystyrene panels.

- Use: Ideal for remodelling projects with limited outside modifications.

- Advantages: Low cost and no need for outside construction.

- Cons: Less usable space; if built incorrectly, it results in thermal bridging.

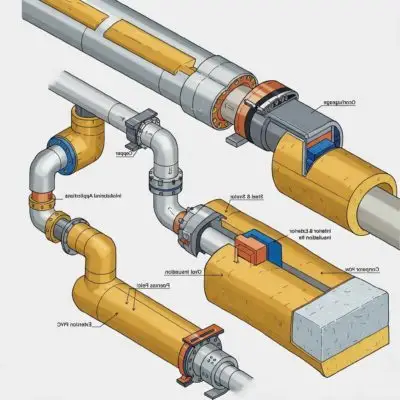

2. Insulation for Ducts and Pipes

- Method: Using fibreglass, Armaflex sheets, or elastomeric foam to wrap pipes.

- Use: Frequently found in plumbing and HVAC systems.

- Benefits: Lowers energy costs and stops heat loss.

- Cons: To prevent gaps, exact fitting is necessary.

3. Insulation for the Roof and Floor

- Method: Between joists, mineral wool or stiff foam boards are installed.

- Use: Increases thermal comfort.

- Benefits: Lowers energy consumption and prevents thermal bridging.

- Cons: Lifting the roof or flooring may be necessary.

Exterior Insulation Techniques (ITE)

1. Systems for Insulating External Walls (EWIS)

- Technique: Mounting insulating boards on walls and then covering them with cladding or protective render.

- Materials: Phenolic boards, rock wool, and expanded polystyrene (EPS).

- Advantages: Preserves interior space and improves the beauty of the façade.

- Cons: May need planning clearances; higher initial cost.

2. External Insulation for Roofs

- Method: Installing waterproof membranes over the insulated roof deck.

- Materials: extruded polystyrene (XPS) and polyisocyanurate (PIR).

- Advantages: Protects structural parts and has excellent thermal performance.

- Cons: More complicated installation.

3. Insulation for Underground Pipes

- Method: Applying waterproofing wraps and layers of rigid insulation, or using pre-insulated pipe systems.

- Application: Perfect for industrial and district heating systems.

- Advantages: Increases system durability and stops heat loss.

- Cons: It could be necessary to excavate.

Principal Advantages of Calorifugeage

1. Efficiency in Energy Use

Insulation minimises the need for heating or cooling by minimising heat gain and loss, which saves a significant amount of energy.

2. Financial Savings

Although there is an initial outlay, calorifugeage lowers energy costs over time and, by safeguarding equipment, lowers maintenance expenses.

3. Effects on the Environment

A smaller carbon footprint from increased energy efficiency enables homes and businesses to support climate goals.

4. Control of Condensation

By preventing condensation on walls and pipes, proper insulation lowers the possibility of material deterioration and the growth of mould.

5. Soundproofing

Additionally, some materials provide soundproofing, which makes the interior more pleasant.

6. System Durability

Insulated systems have a longer operational life because they are less susceptible to temperature-induced wear and tear.

Materials Used in Calorifugeage

| Material | Thermal Conductivity (W/m.K) | Application | Pros | Cons |

|---|---|---|---|---|

| Mineral Wool | 0.035 – 0.045 | Walls, ceilings, ducts | Fire-resistant, soundproof | Can absorb moisture |

| Expanded Polystyrene | 0.030 – 0.040 | Walls, façades, underground | Lightweight, low cost | Flammable without treatment |

| Extruded Polystyrene | 0.029 – 0.035 | Roofs, floors | Water-resistant, durable | Less breathable |

| Polyurethane Foam | 0.022 – 0.028 | Roofs, cavities | High insulation value | Requires skilled installation |

| Armaflex | 0.035 – 0.038 | Pipes and HVAC systems | Flexible, mould-resistant | Limited thickness options |

Price Guide 2025 (Estimated)

Interior Insulation

| Type | Price Range (€/m²) | Notes |

| Wall Insulation (Mineral Wool) | 50 – 90 | Lower cost, reduced space |

| Pipe Insulation (Armaflex) | 10 – 30 per meter | Depends on the pipe diameter |

| Roof/Floor Insulation | 60 – 100 | Based on access and materials |

Exterior Insulation

| Type | Price Range (€/m²) | Notes |

| Wall Insulation (EPS/Render) | 90 – 150 | Includes finish |

| Roof Exterior (XPS, PIR) | 100 – 160 | May include waterproofing |

| Underground Pipe Insulation | 80 – 120 per meter | Excludes excavation |

Tip: Costs vary based on project size, complexity, and region. Request multiple quotes from certified professionals.

Government Assistance and Incentives (EU & France)

Several initiatives are still in place in 2025 to encourage energy-efficient remodelling:

- MaPrimeRénov: Provides subsidies according on home income and degree of energy efficiency.

- Energy suppliers are required by CEE (Certificats d’Économies d’Énergie) to promote energy-saving initiatives.

- Certain environmentally friendly upgrades are eligible for tax credits. Before beginning a project, be sure you are eligible and that the regulations are up to date.

How to Pick the Best Insulation Plan

- Evaluate Your Building: To find regions of heat loss, do a thermal audit.

- Establish Your Objectives: Environmental Impact, Comfort, or Energy Savings?

- Analyse ROI by weighing upfront expenses against long-term savings.

- Choose Materials: Insulate according to your budget, space, and climate.

- Employ Experts: Use certified installers to guarantee quality and compliance.

Concluding remarks

For 2025 and beyond, calorifugeage—internal or external—is a wise investment. Improving the thermal performance of your building is now simpler than ever because of new materials, better methods, and generous financial incentives. Well-planned insulation provides both immediate comfort and long-term benefit, whether you’re managing an industrial site, remodelling a home, or improving a corporate facility. Begin your insulation adventure now; the environment, your comfort, and your pocketbook will all appreciate it.